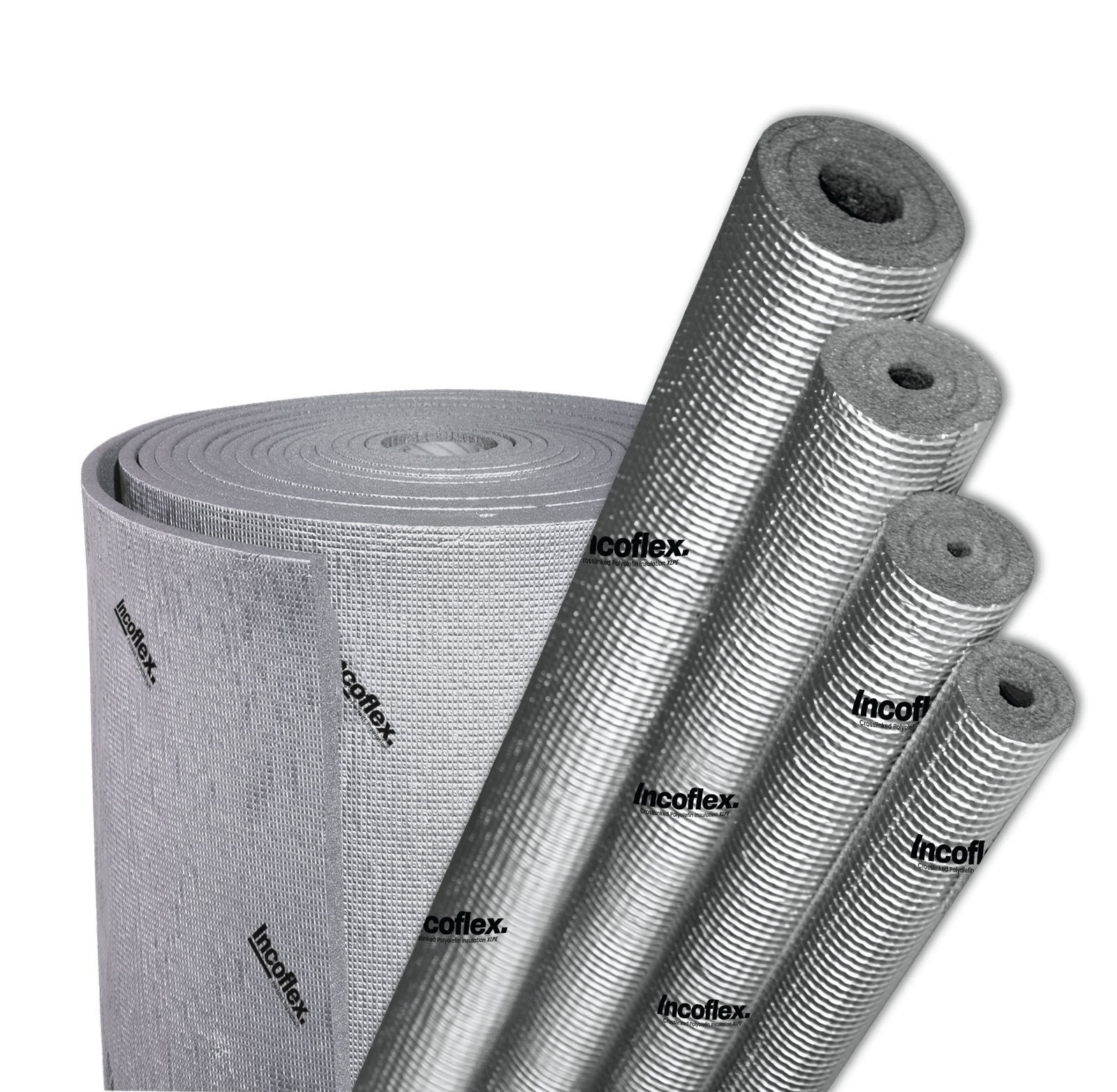

Incoflex XLPE AP - Aluminum Foil-faced

Incoflex XLPE AP tubes and sheets offer improved thermal efficiency, moisture resistance, and durability. Improved Thermal Efficiency Built-in Vapor Barrier Durability & Protection Easy to Clean & Maintain Ideal for Indoor & High-Humidity Applications. Recommended for HVAC ducts, chilled water lines, and refrigeration systems. Meets fire reaction requirements for HVAC, building, and construction applications. Recommended for outdoor installations with additional site-applied weather resistance jacketing or coating

| PROPERTY | VALUE / RESULT | STANDARD TEST METHOD |

| Density | 25 to 35 Kg/m³ | ASTM C1427 |

| Service Temperature (foam only) | -80°C to 120°C | ASTM C177 |

| Thermal Conductivity at mean temperature | 23°C @ 0.033 W/mK | ASTM C518 / ASTM C177 |

|

Water Vapour Transmission Water Vapour Permeability |

≤ 7.29×10⁹ g/Pa·s·m 0.05 perm-inch |

ASTM E96 ASTM E96 |

|

Vapour Diffusion Resistance Factor (μ) Water Absorption (Liquid phase) |

> 80,000 < 0.2% (by volume) |

BS EN 12086 ASTM C209 |

|

Resistance To Fungi Resistance To Bacteria CFC & HCFC Free VOC Level (Green Star Rating) |

No Growth No Growth Comply Low VOC Emitting |

ASTM G21 ISO 22196 – ASTM D5116 |

|

FIRE AND SMOKE PERFORMANCE Surface Burning Characteristics Surface Spread of Flame Classification of Reaction to Fire |

Class A (FSI<25 and SDI<50) Class 0 B–s1,d0 |

ASTM E84 BS 476 part 6 and 7 EN 13501-1 |

| VOC Emissions |

TVOC’s ≤ 0.5 mg/m²/h Formaldehyde: ≤ 0.05 ppm Individual VOCs: ≤ 0.05 ppm for specific VOCs |

CDPH V1.2 LEED V1.4 GREENGUARD |

Cross-linked closed-cell polyolefin thermal insulation foam

Incoflex XLPE is a high performance cross-linked polyolefin thermal insulation material designed for superior energy efficiency and durability. It complies with ASTM C1427, ensuring high-quality standards for closed-cell thermal insulation. This versatile insulation solution is widely used in building and construction, HVAC, refrigeration, plumbing, oil / gas and other industrial applications, providing excellent thermal resistance, moisture resistance, and long-term performance

Reducing CO₂ Emissions Through Superior Thermal Efficiency

Reduces CO₂ Emissions – By improving thermal efficiency and reducing energy demand, Incoflex XLPE helps cut carbon dioxide (CO₂) emissions, supporting global efforts toward environmental sustainability

Health, Environment, and Indoor Air Quality Benefits of Incoflex XLPE

Incoflex XLPE has a minimized volatile organic compound (VOC) emission, contributing to better indoor air quality and a healthier environment. Unlike some insulation materials, Incoflex XLPE does not release harmful fibers or particles into the air, reducing respiratory risks. Its closed-cell structure prevents moisture buildup, which helps inhibit the growth of mold, mildew, and bacteria, improving hygiene and air quality. Produced with environmentally responsible processes, reducing waste and promoting sustainability. Helps lower energy consumption in HVAC, refrigeration, and plumbing systems, reducing carbon footprints and supporting green building initiatives. Free from CFCs, HCFCs, and other ozone-depleting substances, making it a safe choice

Features

- Superior Thermal Insulation – Provides excellent heat resistance, reducing energy loss

- Moisture and Water Vapor Resistance – Minimizes condensation and prevents mold growth.

- Durable and Long-Lasting – Resistant to wear, tear, and environmental factors.

- Lightweight & Flexible – Easy to install and adapt to various applications.

- Wide Application Range – Ideal for oil & gas, building & construction, HVAC&R, plumbing, and any industry.

- Low Thermal Conductivity – Enhances energy efficiency in piping and ductwork.

- Resistance against Chemicals and Corrosion – Protects against degradation from chemicals and environmental exposure.

- Fire-Retardant Properties – Offers improved safety in construction and industrial settings.

- Prevents Corrosion - does not contain halogenated components.